Find out how Bulk Plastic Containers help save space effectively

Wiki Article

Everything About Mass Plastic Containers: Benefits, Applications, and Sector Insights

Mass plastic containers play a significant role in numerous markets, using advantages that enhance effectiveness and sustainability. Their lightweight nature minimizes shipping prices, while their longevity guarantees risk-free storage space and transport of varied products. As firms progressively seek environment-friendly services, the need for these containers is expanding. This increases essential questions about the materials used and the fads influencing their style. What effects do these elements have for the future of mass plastic containers?Benefits of Bulk Plastic Containers

Mass plastic containers provide a wide variety of benefits in different markets. Their lightweight style especially decreases transportation costs, enabling reliable logistics and less complicated handling. Furthermore, these containers supply sturdiness and resistance to weather elements, chemicals, and physical effect, ensuring the risk-free storage space and transportation of goods. The adaptability of mass plastic containers allows them to be formed right into numerous sizes and shapes, providing to specific industry requirements.

Common Applications Throughout Industries

While numerous markets utilize bulk plastic containers, their applications are particularly prominent in fields such as food and drink, drugs, farming, and production. In the food and drink sector, these containers are necessary for storing and carrying items like grains, fluids, and prepared dishes, making certain quality and security. The pharmaceutical industry counts on mass plastic containers for safe storage of vaccines and medicines, keeping conformity with strict regulations.In farming, these containers help with efficient handling and transportation of produce, plant foods, and chemicals, while likewise sustaining sustainable practices with recyclability. Manufacturing sectors utilize bulk plastic containers for components storage and setting up line operations, advertising organization and workflow effectiveness. Additionally, these containers offer a considerable role in logistics and supply chain administration, simplifying the motion of goods across numerous markets. Overall, the convenience of mass plastic containers makes them important throughout multiple markets.

Product and Style Factors To Consider

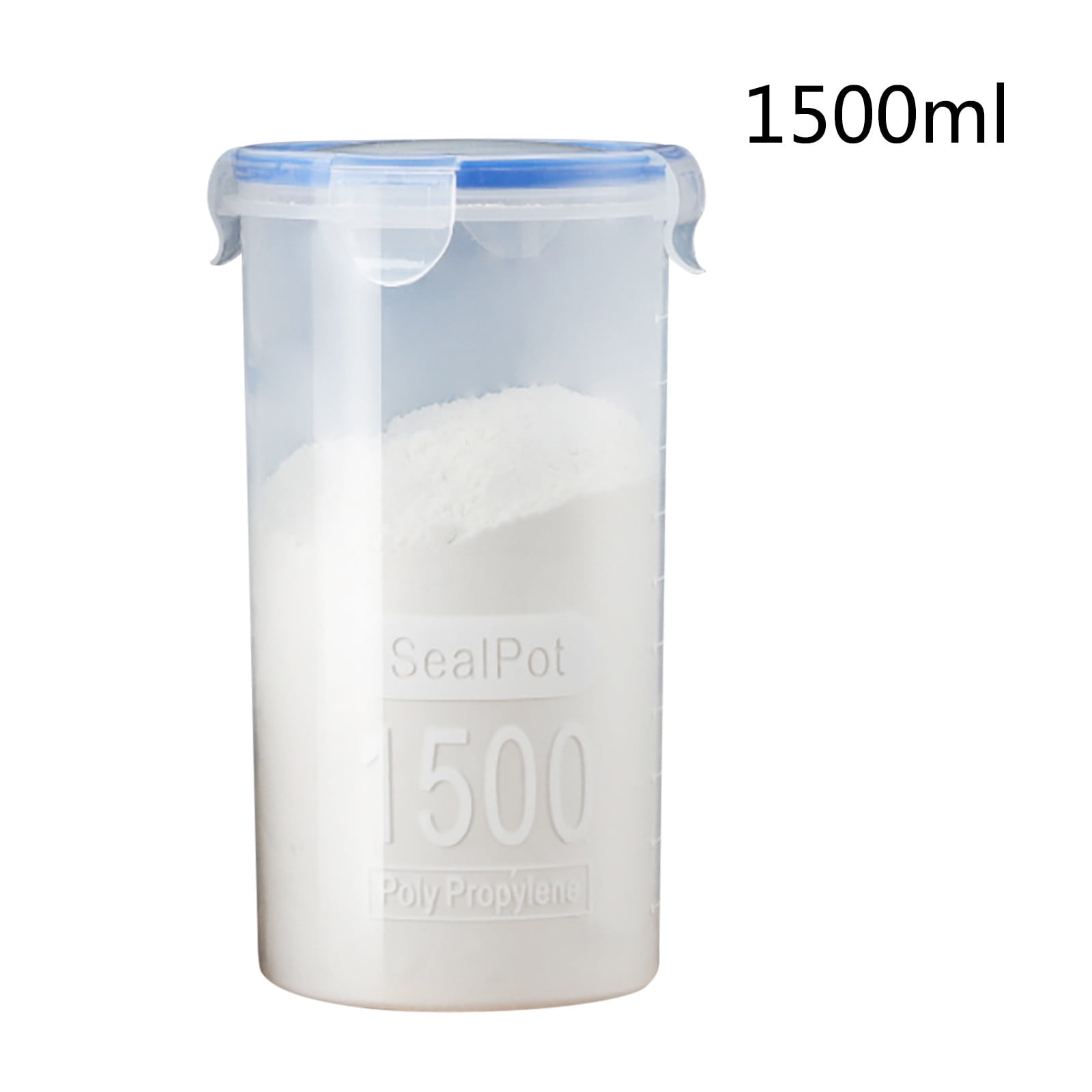

When selecting mass plastic containers, product and design factors to consider play an important duty in ensuring performance and compliance with market criteria. The choice of material considerably impacts the container's toughness, weight ability, and resistance to environmental elements. Typical products consist of high-density polyethylene (HDPE) and polypropylene, known for their stamina and chemical resistance.Layout facets, such as shape, closure, and dimension systems, likewise affect use. Containers with ergonomic handles and stackable designs improve storage performance and convenience of transportation. Additionally, features like venting or drainage holes might be essential for specific applications, enabling air circulation or liquid removal.

Compliance with safety regulations, such as FDA approvals for food-grade applications, is important. plastic bulk containers. Generally, cautious factor to consider of materials and style can enhance performance and longevity, ensuring that bulk plastic containers fulfill the varied requirements of different markets successfully

Patterns wholesale Plastic Container Usage

As industries evolve, the usage of mass plastic containers is significantly affected by sustainability and performance. Firms are selecting green products, such as recycled plastics, to lessen environmental impact while maintaining durability. This change is driven by customer demand for regulative pressures and lasting practices focused on lowering plastic waste.In addition, the pattern towards automation in logistics and supply chain administration is reshaping container layouts. Bulk containers are currently being engineered for compatibility with automated systems, boosting operational performance. Lightweight styles are likewise obtaining grip, as they reduce delivery costs and power consumption throughout transportation.

Additionally, personalization is coming to be a centerpiece, permitting companies to customize containers to particular demands, thus maximizing space and performance. These trends show a more comprehensive commitment to sustainability, technology, and efficiency within different industries, ensuring that bulk plastic containers proceed to play an important duty in modern supply chains.

Finest Practices for Storage Space and Transport

Effective storage and transport of mass plastic containers require adherence to finest techniques that enhance safety and effectiveness. Initially, containers should be stacked safely, ensuring that weight is uniformly dispersed to avoid tipping or damage. Using pallets can assist in less complicated movement and safeguard the containers from ground wetness. Furthermore, correct labeling is important for quick recognition and monitoring throughout transportation.Temperature level control is another vital aspect; extremes can endanger the stability of the products. plastic bulk containers When needed, it is a good idea to store containers in a climate-controlled environment. For transportation, selecting appropriate vehicles designed for bulk lots warranties security and lessens danger during transit.

Regular evaluations of containers prior to storage space and transportation assistance determine any type of wear or damage, permitting prompt upkeep or substitute. By following these best techniques, companies can enhance the lifecycle of bulk plastic containers while maintaining functional effectiveness.

Often Asked Questions

Are Bulk Plastic Containers Recyclable After Usage?

Yes, bulk plastic containers are commonly recyclable after use. Recyclability depends on the material type and local recycling programs. Correct cleaning and sorting are important to assure they are accepted by reusing facilities.

What Is the Life Expectancy of Bulk Plastic Containers?

The life-span of bulk plastic containers commonly ranges from 5 to ten years, relying on usage problems, worldly high quality, and ecological elements. Bulk Plastic Containers. Appropriate upkeep can extend their longevity, making them a lasting storage space solution

Can Bulk Plastic Containers Be Custom-made?

Yes, bulk plastic containers can be tailored. Makers usually provide alternatives for size, product, branding, and shade, enabling businesses to tailor containers to their particular demands and boost their product presentation and capability.Just How Do Bulk Plastic Containers Compare in Cost to Alternatives?

Bulk plastic containers normally supply a reduced cost compared to alternatives like metal or glass, because of their lightweight nature and toughness. This makes them a cost-effective choice for companies needing effective storage options.Exist Safety Regulations for Using Bulk Plastic Containers?

Bulk plastic containers play a considerable role in numerous markets, providing advantages that boost effectiveness and sustainability. While various industries make use of bulk plastic containers, their applications are especially popular in sectors such as food and drink, pharmaceuticals, farming, and production. Manufacturing industries use bulk plastic containers for components storage and setting up line procedures, promoting company and workflow performance. When choosing mass plastic containers, material and layout considerations play an important duty in making sure functionality and conformity with market criteria. As markets advance, the usage of mass plastic containers is progressively affected by sustainability and efficiency.

Report this wiki page